Choosing the right explosion proof camera can feel overwhelming, especially when it comes to understanding certification requirements. Two of the most common standards are ATEX certified cameras vs UL explosion proof cameras. But what do these certifications mean, and which one is right for you?

This guide will break down both certifications in simple terms, highlight their key differences, and help you decide which type of camera fits your needs best.

Table of Contents

- Why Explosion Proof Certifications Matter

- What is ATEX Certification?

- What is UL Certification?

- ATEX Certified Cameras vs UL Explosion Proof Cameras: Key Differences

- When to Choose ATEX Certified Cameras

- When to Choose UL Explosion Proof Cameras

- Global Operations: Do You Need Both?

- Future Trends in Explosion Proof Standards

- Comparison Table: ATEX vs UL

- Conclusion

Why Explosion Proof Certifications Matter

In hazardous environments like oil refineries, chemical plants, or mining operations, even a tiny spark can trigger an explosion. That’s why explosion proof cameras must meet strict certification standards. These certifications ensure your equipment won’t become an ignition source, keeping people and assets safe.

Beyond protecting lives, certifications also ensure compliance with government regulations. Using non-certified equipment can lead to heavy fines, shutdowns, or loss of insurance coverage. For industries like oil & gas or pharmaceuticals, a single non-compliance issue could halt production for weeks, costing millions.

What is ATEX Certification?

ATEX certification comes from the European Union. It’s mandatory for equipment used in environments with explosive atmospheres.

Quick facts about ATEX:

- Required in all EU countries.

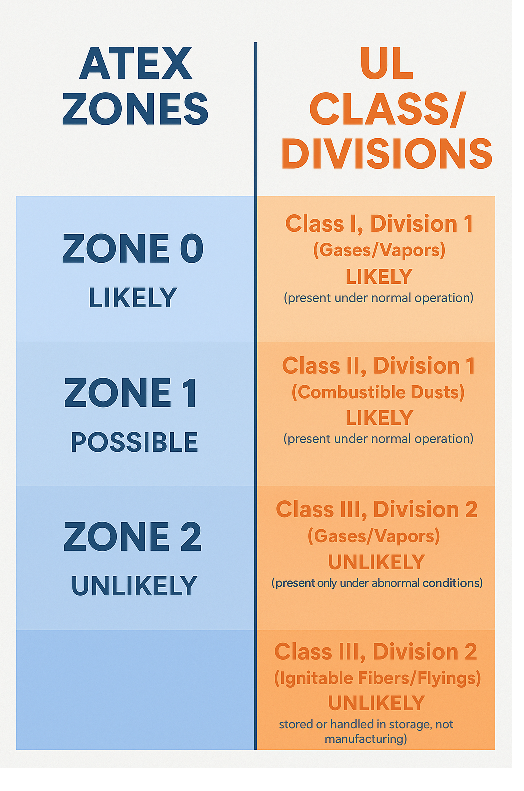

- Uses a Zone system (Zone 0, Zone 1, Zone 2).

- Designed to prevent ignition sources.

- Widely recognized across Europe.

Learn more from the European Commission on ATEX.

ATEX Zone Classifications:

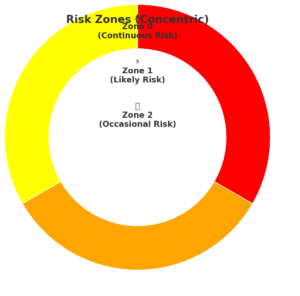

🔴 Zone 0 (Continuous Risk) in the center, where explosive gases or vapors are present continuously or for long periods.

🟠 Zone 1 (Likely Risk) in the middle, where explosive atmospheres are likely during normal operation.

🟡 Zone 2 (Occasional Risk) on the outside, where explosive atmospheres are unlikely but possible under abnormal conditions.

ATEX also applies to dust hazards:

- Zone 20: Dust present continuously.

- Zone 21: Dust present occasionally.

- Zone 22: Dust present only rarely.

This makes ATEX highly versatile for industries ranging from oil rigs to flour mills.

What is UL Certification?

UL (Underwriters Laboratories) certification is the North American equivalent. It ensures electrical devices are safe in hazardous areas.

Quick facts about UL:

- Common in the United States and Canada.

- Uses a Class/Division system (Class I, Division 1 or 2).

- Tests equipment to withstand explosive conditions.

- Known for tough, reliable safety standards.

Explore more at the UL Standards & Engagement site.

UL Hazardous Location Classifications:

Class I – Gases and vapors (methane, propane, hydrogen).

Class II – Combustible dusts (grain, coal, metal dust).

Class III – Fibers and flying’s (wood, textiles).

Divisions further define risk:

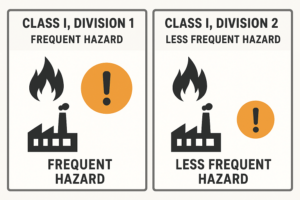

- Division 1: Hazard is present during normal operation.

- Division 2: Hazard is present only under abnormal conditions.

ATEX Certified Cameras vs UL Explosion Proof Cameras: Key Differences

Both certifications aim to keep hazardous environments safe, but they approach risk differently.

1. Where They Apply

ATEX: Europe 🇺🇸 UL: North America

2. How They Classify Risk

- ATEX → Zone system

- UL → Class/Division system

3. Main Focus

- ATEX → Prevent ignition entirely

- UL → Ensure safe operation under hazards

When to Choose ATEX Certified Cameras

Choose ATEX certified cameras if:

- You operate in EU or EEA countries.

- Your facility uses the Zone classification system.

- You need compliance with European regulations.

When to Choose UL Explosion Proof Cameras

Choose UL explosion proof cameras if:

- You work in the US or Canada.

- Your site is regulated by the Class/Division system.

- You want gear that’s passed UL’s strict testing.

Global Operations: Do You Need Both?

If your business operates internationally, investing in cameras with dual ATEX + UL certifications simplifies compliance. While they may cost more upfront, they eliminate the need for multiple product lines and reduce audit headaches. Many global manufacturers are now offering dual-certified devices for oil & gas, marine, and energy companies with operations across continents.

Future Trends in Explosion Proof Standards

Standards are evolving to keep up with new technology. One major trend is the rise of IECEx, a globally recognized certification that aligns with both ATEX and UL principles. More manufacturers are moving toward multi-standard compliance to cover EU, North American, and international requirements with one product line. This trend is especially relevant as industries adopt smart devices, IoT monitoring, and AI-enabled safety systems.

Comparison Table: ATEX vs UL

| Feature | ATEX Certified Cameras | UL Explosion Proof Cameras |

|---|---|---|

| Region | European Union | North America |

| Standard | EU Directives 2014/34/EU | UL 1203, UL 60079 |

| Classification | Zone (0, 1, 2, 20, 21, 22) | Class (I, II, III) / Division (1 or 2) |

| Risk Approach | Prevent ignition | Operate safely in hazards |

| Market Requirement | Mandatory in EU | Mandatory in US/Canada |

Conclusion

When comparing ATEX certified cameras vs UL explosion proof cameras, the right choice comes down to your location and regulations. Both certifications keep people and facilities safe, but they’re tailored for different regions. If you operate globally, choosing cameras with both certifications ensures compliance everywhere.

Contact Us

Still unsure which certification is right for your project? Our team of experts can help you select the best explosion proof camera for your facility.

Email: [email protected]

Phone: +1(214)635-4855

Visit: www.veilux.net

Let’s make your operations safer together.