In industries like oil and gas, chemical processing, and mining, safety is non-negotiable. With combustible gases, vapors, and dust present, the smallest spark from improperly designed equipment can result in catastrophic explosions. That’s why explosion-proof surveillance systems are essential for operations in hazardous environments. These specialized security products are engineered to prevent ignition sources, ensuring safety while still providing the monitoring capabilities that critical infrastructure requires.

This article explores the importance of explosion-proof surveillance, certification standards, compliance guidelines, and best practices for implementing these systems.

Understanding Explosion-Proof Surveillance Systems

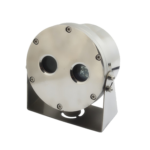

Explosion-proof surveillance systems are designed to contain any sparks or flames that could escape from the internal components of cameras, housings, or supporting equipment. Unlike standard CCTV cameras, these units are engineered with heavy-duty enclosures and seals that ensure safety without compromising image quality or monitoring functions.

Industries that benefit from these systems include:

- Oil and gas refineries: High-risk environments with volatile gases and liquids.

- Petrochemical plants: Where combustible materials are processed and stored.

- Mining operations: Dusty and flammable atmospheres.

- Industrial manufacturing: Facilities with solvents, fuels, or hazardous chemicals.

In these sectors, explosion-proof surveillance is more than a compliance requirement, it’s an operational safeguard that protects lives, assets, and business continuity.

Understanding Certifications

Not all explosion-proof equipment is created equal. Certifications ensure that surveillance systems meet strict international and regional safety standards. For oil and gas operators, choosing properly certified equipment is both a compliance issue and a safety imperative.

Some of the key certifications include:

1. ATEX Certification (Europe)

ATEX certification ensures equipment is safe for explosive atmospheres within the European Union. It covers both electrical and non-electrical equipment, defining categories of equipment based on the zone of installation.

2. IECEx Certification (Global)

The International Electrotechnical Commission (IEC) provides IECEx certification, a globally recognized standard. It verifies that equipment has been tested and complies with international safety standards for explosive environments.

3. UL and CSA Certification (North America)

Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) test and certify explosion-proof equipment for use in the United States and Canada. Their certifications align with ANSI standards for hazardous environments.

4. Local and Industry-Specific Certifications

Beyond the major standards, certain regions and industries require compliance with additional certifications. Operators must check with regulatory authorities to confirm what certifications apply.

For a deeper dive into certifications, contact Veilux.net

Compliance Guidelines

Meeting certification standards is only one part of the equation. Oil and gas companies must ensure full compliance with occupational safety regulations and industry best practices.

Key Compliance Considerations:

- Hazardous Area Classification: Determine whether your facility has Zone 1, Zone 2, Division 1, or Division 2 hazardous locations. Surveillance equipment must match the classification.

- Installation Requirements: Certified explosion-proof cameras must be installed according to manufacturer instructions and safety codes. Improper installation can void certification.

- Regular Inspections and Maintenance: Surveillance systems should undergo periodic inspections to ensure seals, gaskets, and enclosures remain intact.

- Integration with Safety Systems: Cameras should integrate with broader plant monitoring systems, ensuring operators can respond quickly to safety events.

- Documentation and Audits: Maintain detailed records of certification documents, maintenance logs, and compliance audits to satisfy regulators and internal safety policies.

Compliance doesn’t just keep your business safe, it also minimizes liability and ensures uninterrupted operations.

Best Practices for Implementing Explosion-Proof Surveillance Systems

Once compliance is addressed, companies should focus on maximizing performance and safety. Here are best practices for deploying explosion-proof surveillance:

1. Select the Right Products

Choose surveillance systems specifically engineered for hazardous environments. Ensure they come with valid certifications and warranties. Explore options at Veilux Products.

2. Assess Environmental Conditions

Consider not only explosion risks but also extreme weather, saltwater exposure, vibration, and dust when selecting equipment.

3. Leverage Advanced Features

Modern explosion-proof cameras offer:

- Infrared night vision

- High-definition recording

- Remote monitoring and control

- Integration with access control systems

These features enhance both security and operational efficiency.

4. Train Staff for Safety

Employees responsible for monitoring, maintaining, or installing surveillance systems should be trained in hazardous location safety standards.

5. Plan for Scalability

As facilities expand, ensure surveillance systems can scale with new zones and hazards. Flexible systems save costs in the long term.

Conclusion

In oil and gas and other high-risk industries, explosion-proof surveillance systems are more than security tools, they are critical safety assets. Choosing certified equipment, complying with international standards, and implementing best practices ensures not only regulatory compliance but also operational safety and efficiency.

By investing in certified systems, companies protect their workforce, safeguard assets, and strengthen their commitment to safety compliance. For businesses operating in hazardous environments, explosion-proof surveillance is not optional, it’s essential.