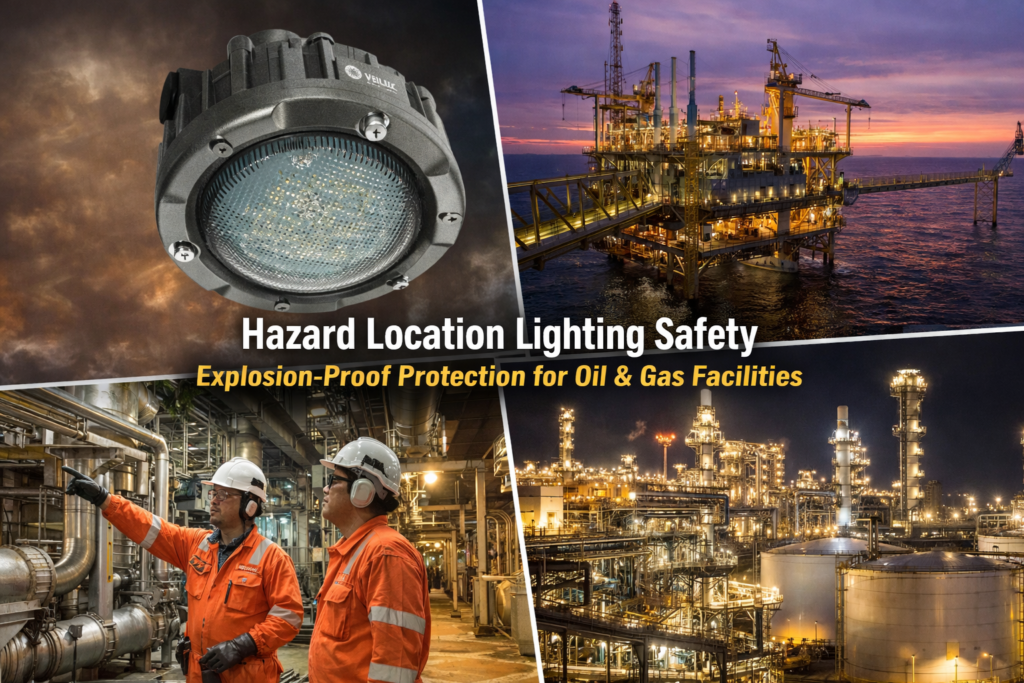

In oil and gas facilities, safety isn’t theoretical — it’s operational. Every system, every component, and every procedure is designed to reduce risk in environments where flammable gases, combustible vapors, and volatile chemicals are part of daily operations.

That’s why hazard location lighting safety plays such a critical role.

Lighting in these facilities does far more than illuminate workspaces. In classified hazardous areas, improperly selected fixtures can become ignition sources. The right explosion-proof lighting strategy, however, becomes a powerful layer of protection that supports compliance, visibility, and long-term operational stability.

Let’s explore how hazard location lighting safety directly enhances protection in oil and gas facilities, and why a solution-driven approach matters.

Understanding Hazardous Location Classifications

Oil and gas environments are regulated under strict hazardous location standards established by organizations such as the Occupational Safety and Health Administration and the National Fire Protection Association.

Under these frameworks, hazardous areas are classified by:

- Class I – Locations containing flammable gases or vapors

- Division 1 – Explosive mixtures present during normal operations

- Division 2 – Explosive mixtures present only under abnormal conditions

These classifications directly determine the requirements for hazard location lighting safety. Lighting installed in these areas must be engineered and certified to prevent sparks, arcs, or excessive surface temperatures from igniting surrounding atmospheres.

Without compliant fixtures, even routine electrical activity can create unnecessary risk.

What Explosion-Proof Lighting Really Means

There’s a common misunderstanding that explosion-proof lighting prevents explosions entirely. In reality, these fixtures are designed to contain any internal ignition event so it cannot escape and ignite external gases.

Certified fixtures meet standards from organizations such as:

- Underwriters Laboratories (UL certification)

- International Electrotechnical Commission (IECEx system)

- ATEX (European compliance directive)

These certifications form the technical backbone of hazard location lighting safety in oil and gas facilities.

But certification alone isn’t enough. Proper selection, placement, and environmental evaluation are equally important, which is where working with an experienced lighting partner becomes critical.

Why Hazard Location Lighting Safety Is So Critical in Oil & Gas

Oil and gas facilities routinely handle methane, propane, hydrogen sulfide, and other highly flammable substances. Even a small ignition source can escalate rapidly.

Here’s how strong hazard location lighting safety directly protects operations:

1. Reduces Ignition Risk

Standard lighting fixtures can produce arcs or elevated temperatures. Explosion-proof LED systems isolate electrical components within sealed housings, dramatically strengthening hazard location lighting safety in volatile environments.

2. Improves Worker Visibility

Proper illumination improves clarity around walkways, valves, staircases, and control panels. In hazardous areas, shadowed spaces and inconsistent lighting increase the risk of slips, trips, and operational errors. Effective hazard location lighting safety enhances both environmental and human safety.

3. Minimizes Maintenance Exposure

Modern LED explosion-proof systems offer extended service life, reducing the need for frequent fixture replacement. Fewer maintenance interventions in classified zones directly support long-term hazard location lighting safety.

4. Supports Regulatory Compliance

Failure to meet hazardous location standards can result in citations, fines, or operational shutdowns. A well-designed hazard location lighting safety strategy ensures ongoing compliance and inspection readiness.

Beyond Fixtures: The Importance of a Solution-Driven Approach

Many facilities focus solely on purchasing certified fixtures. However, true hazard location lighting safety requires more than selecting a product from a catalog.

It involves:

- Reviewing hazardous classifications

- Evaluating environmental conditions

- Considering mounting height and beam angles

- Conducting photometric analysis

- Planning for long-term performance

At Veilux, we provide comprehensive hazard location lighting solutions tailored to oil and gas environments. Rather than manufacturing fixtures, we assess each facility’s operational needs and recommend certified explosion-proof lighting systems that align with regulatory standards and real-world conditions.

You can explore our full range of explosion-proof and hazardous area lighting options here.

Key Design Factors That Strengthen Hazard Location Lighting Safety

Effective hazard location lighting safety requires attention to environmental realities unique to oil and gas operations.

Corrosion Resistance

Offshore and refinery environments expose equipment to saltwater, chemicals, and harsh weather. Corrosion-resistant housings preserve fixture integrity and long-term compliance.

Thermal Management

Excess surface heat can pose ignition risks. Properly engineered LED systems maintain lower operating temperatures, enhancing hazard location lighting safety.

Vibration Durability

Drilling rigs and compressor stations often experience heavy vibration. Fixtures must withstand these conditions without compromising seals or electrical stability.

Photometric Planning

Uniform illumination eliminates shadows and dark zones. Strategic placement ensures consistent light distribution, a frequently overlooked component of hazard location lighting safety.

Our team also supports lighting layout and photometric planning to help facilities optimize placement while meeting compliance requirements.

Applications Across the Oil & Gas Value Chain

Hazard location lighting safety applies across upstream, midstream, and downstream operations, including:

- Offshore platforms

- Onshore drilling rigs

- Refineries

- Gas processing plants

- Tank farms

- Pump stations

- Pipeline compressor facilities

Each area may require different Class and Division ratings. A comprehensive evaluation ensures the selected lighting aligns precisely with hazardous classifications and environmental demands.

Aligning with Industry Standards

For facilities reviewing their current compliance posture, it’s important to align lighting systems with standards outlined in the National Electrical Code (NFPA 70) and related OSHA regulations.

Regular audits of lighting infrastructure can reveal outdated fixtures or misclassified zones that may compromise hazard location lighting safety

The Long-Term Value of Hazard Location Lighting Safety

While explosion-proof lighting is a compliance requirement, its impact extends further:

- Reduced risk exposure

- Improved workforce confidence

- Lower maintenance costs

- Enhanced operational reliability

- Greater insurance and regulatory stability

In oil and gas operations, a proactive approach to hazard location lighting safety is not simply about meeting standards — it’s about protecting people, assets, and production continuity.

Final Thoughts

In hazardous oil and gas environments, lighting cannot be an afterthought. Every fixture installed in a classified zone must actively contribute to hazard location lighting safety.

Explosion-proof lighting enhances safety by:

- Containing potential ignition sources

- Supporting clear visibility

- Meeting strict certification standards

- Reducing maintenance exposure

- Strengthening long-term compliance

At Veilux, we work as a lighting solution provider — helping facilities assess risks, select certified systems, and design layouts that align with real-world operational demands.

Because when it comes to hazardous environments, safety isn’t just about brighter light.

It’s about smarter protection.