Table of Contents

- Introduction

- What Makes an Explosion-Proof Camera Essential?

- Factors to Consider

- Camera Types

- Installation Tips

- Conclusion

Introduction

Choosing the right explosion-proof camera for flammable environments is one of the most critical decisions for facilities operating in hazardous locations. Industries such as oil and gas, chemical processing, pharmaceuticals, refineries, and mining must use certified cameras designed to prevent ignition in areas with explosive gases, vapors, liquids, and dust.

What Makes an Explosion-Proof Camera Essential?

Industrial sites with flammable liquids, vapors, dust, or gases fall under strict regulations for safety monitoring. A certified explosion-proof camera for flammable environments provides a barrier that prevents sparks, heat, or electrical discharge from escaping the camera housing.

These cameras must meet global standards and hazardous area classifications such as:

- ATEX

- IECEx

- UL or cUL

- IP67/IP68 weatherproof ratings

Using the wrong camera in a flammable area can result in catastrophic accidents, equipment failures, injuries, and legal penalties. Staying compliant with organizations such as the National Fire Protection Association (NFPA) and OSHA is essential.

Factors to Consider When Choosing an Explosion-Proof Camera for Flammable Environments

When selecting an explosion-proof camera for flammable environments, start by carefully evaluating the following criteria:

1. Hazardous Area Classification

Identify the exact zone, class, or division where the camera will be used. Each classification determines the level of protection required. For example:

- Class I – Flammable gases or vapors present

- Class II – Combustible dust

- Zone 1 / Zone 2 – Areas where explosive atmospheres are present continuously or occasionally

Choosing the correct certification ensures compliance and safety.

2. Certification Standards

Look for third-party certification marks such as:

- ATEX

- IECEx

- UL, cUL

- IP67/IP68 weatherproof ratings

Equipment without the proper certification cannot legally be used in flammable zones.

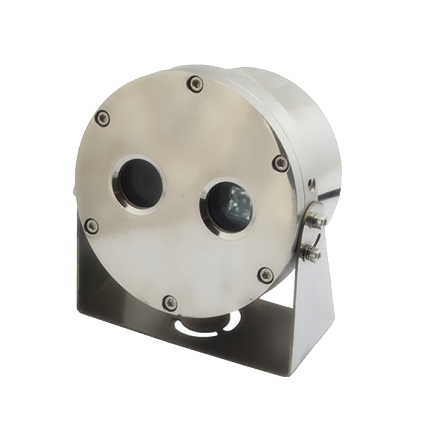

3. Camera Housing Material

Explosion-proof housings are typically built from:

- 304 or 316L stainless steel

- Aluminum alloy

- High-strength corrosion-resistant materials

For offshore and oilfield applications, 316 stainless steel provides superior durability.

4. Video Resolution & Performance

High-definition imaging helps operators detect hazards earlier. Consider:

- 4MP, 6MP, or 8MP (4K) resolution

- Integrated infrared (IR) for low-light

- Wide dynamic range (WDR)

- PTZ (Pan-Tilt-Zoom) capabilities

5. Environmental Considerations

A proper explosion-proof camera for flammable environments must endure:

- Extreme hot/cold temperatures

- Vibration

- Humidity and moisture

- Dust or chemical exposure

6. Connectivity & Integration

Your camera should integrate easily with:

- Existing NVRs

- VMS platforms

- Monitoring control rooms

To explore integrated solutions, visit Veilux Solutions → https://www.veilux.net/solutions

Camera Types for Explosion-Proof Applications

There are several types of explosion-proof cameras for flammable environments, each suited for specific tasks.

1. Fixed Explosion-Proof Cameras

Best for general monitoring or static areas. These are durable and ideal for corridors, walkways, equipment rooms, and storage facilities.

2. PTZ Explosion-Proof Cameras

PTZ models allow operators to zoom, pan, and tilt remotely. These are perfect for:

- Offshore platforms

- Drilling rigs

- Chemical plants

- Perimeter security

3. Thermal Explosion-Proof Cameras

Thermal cameras detect heat signatures and temperature changes. Ideal for early detection of:

- Overheating equipment

- Electrical faults

- Gas leaks

4. Compact or Mini Explosion-Proof Cameras

Used in tight or confined spaces where a full-size housing cannot fit.

Recommended Industrial-Grade Camera Options

If you need certified, reliable, and high-performance cameras, explore explosion-proof products from Veilux

Installation Tips for an Explosion-Proof Camera for Flammable Environments

Installing an explosion-proof camera for flammable environments requires precision, proper equipment, and adherence to safety codes.

1. Use Approved Conduit & Seals

All wiring entering the camera housing must use explosion-proof conduit and certified seals to prevent gas ingress.

2. Follow OSHA and NFPA Guidelines

Both OSHA and NFPA provide regulatory installation requirements:

- Use certified labor

- Follow strict cable protection rules

- Maintain safe distances and mounting angles

3. Proper Mounting Location

Ensure the camera is placed where it can achieve the best visibility without creating obstructions for workers or machinery.

4. Perform Regular Maintenance

While explosion-proof cameras are built for long-term durability, they still require:

- Routine lens cleaning

- Housing inspections

- Electrical connection checks

5. Professional Installation Only

Improper installation is a major cause of hazardous environment accidents. Always use trained professionals with hazardous-area certifications.

Conclusion

Choosing the right explosion-proof camera for flammable environments is essential to ensuring safety, compliance, and consistent operational performance. By understanding hazardous area classifications, selecting proper certifications, choosing the right camera type, and following correct installation practices, you can significantly reduce risks in flammable industrial zones.

Whether you’re upgrading your facility or planning a new project, selecting the right explosion-proof solution will protect your team and streamline operations. For certified, reliable surveillance options, explore Veilux explosion-proof products and integrated solutions.